Feel free to use or edit a copy

includes Teacher and Student dashboards

Measure skillsfrom any curriculum

Measure skills

from any curriculum

Tag the questions with any skills you have. Your dashboard will track each student's mastery of each skill.

With a free account, teachers can

- edit the questions

- save a copy for later

- start a class game

- automatically assign follow-up activities based on students’ scores

- assign as homework

- share a link with colleagues

- print as a bubble sheet

14 questions

Show answers

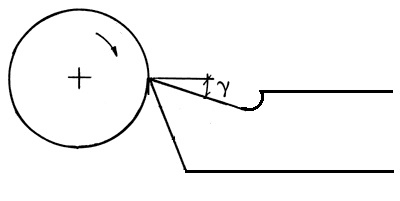

- Q1The turning tool angle ( γ ) shown in figure is calledTool edge angle.Clearance angle.Rake angle.Wedge angle.30s

- Q2The turning tool angle ( α ) shown in figure is calledRake angle.Wedge angle.Tool edge angle.Clearance angle.30s

- Q3The point of Cutting tool bit must be seton center.between center.above center.down center.30s

- Q4The figure shown represents aCorrect setting of the shaping cutting tool.Correct setting of the end mill cutter.Correct setting of the drilling cutting tool.Correct setting of the lathe cutting tool.30s

- Q5Which one of the following factors affecting feed rate?Work piece diameter.Work piece drawing.Work piece length.Work piece material.30s

- Q6In parallel turning on lathe machine , the tool moveOpposite to workpiece axisParallel to workpiece axisSquare to workpiece axisInclined to workpiece axis30s

- Q7An operation for reducing the length of the work-piece isTaper TurningThreadingParallel TurningFacing30s

- Q8The machine part that can be control the angular movement iscompound slideheadstocklathe bedfeed shaft30s

- Q9For supporting the workpiece , we useHead StockThe carriageTool postTail Stock30s

- Q10For holding the turning tool bit , we useTool bitTool postHead StockTool Holder30s

- Q11The 3 jaw Chuck shown in figure is used to tighten aSquare work piece.Flat sheet.Round work piece.Rectangular work piece.30s

- Q12Which one of the following is a lathe safety precaution?Get help to remove dividing head or rotary table.Check that the job is clamped tight in the lathe chuck.Do not touch the ram while the machine is running.Never reach over or near the rotation cutter.30s

- Q13The indicated handles (A,B) are used forSelecting proper spindle speedSelecting proper feed or threading pitchReversing the spindle directionSelecting the threading mechanism30s

- Q14These handles (1,2,3,4) shown in figure are used forSelecting proper speedReversing the spindle rotation directionSelecting proper feed or threading pitchSelecting the threading mechanism30s